Tablet Making Machine

Tablet Making Machine Specification

- Feeding System

- Gravity hopper / Force feeder

- Power Source

- Electric

- Noise Level

- Low ( 70 dB)

- Frequency

- 50/60 Hz

- Operating Temperature

- 10C to 40C

- Function Type

- Compression, Tablet Forming

- Automation Grade

- Automatic

- Speed Mode

- Variable speed

- Machine Type

- Tableting Machine

- Phase

- Single/Three Phase

- Product Type

- Tableting Machine

- General Use

- Pharmaceutical, Chemical, Food Industries

- Material

- Stainless Steel

- Type

- Single/Double Rotary Tablet Press

- Capacity

- Up to 60000 tablets/hour

- Weight (kg)

- Approx. 600 kg

- Product Shape

- Round / Oblong / Custom (as per die)

- Computerized

- Yes

- Control System

- PLC control with touchscreen interface

- Voltage

- 220V / 380V (as per requirement)

- Power

- 2 HP

- Dimension (L*W*H)

- Approx. 950 x 700 x 1600 mm

- Raw Material

- SS304 Stainless Steel

- Feature

- High Efficiency, Easy Operation, Robust Structure

- Color

- Silver

Tablet Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Tablet Making Machine

We are proudly engaged in manufacturing and supplying a technically assorted series of Tablet Making Machine. Extensively used in many pharmaceutical industries, these machines are specifically used for the production purpose of tablets and capsules. These machines reflect cutting edge technology as integrated with the fine and working components. Our Tablet Making Machine is cost effective and can be easily availed from us in diverse specifications and capacities.

Features:

- Withstand harsh conditions

- Easy operations

- Excellent speed

Further Details:

Tablet Making Machine "IKON" CAT. NO. IK-509

For making tablets up to 100 mg and as per size of punch 6 mm. Automatic compression and ejection device with each revolution of the wheel drive, built on heavy cast iron body with accentric pressure system. Stainless steel hopper are provided and connected by a PVC Tube. Easy setting for thickness and hardness of tablets with nuts and locknuts, set of two spanners provided as necessary tools. Die and set of punches are of chromium steel. Fitted on stand .

Versatile and High-Capacity Tablet Production

Engineered to handle a wide range of tablet sizes and shapes, this machine supports production demands with up to 60,000 tablets per hour. Its adaptability, from granule compression to automatic discharge, suits both small batches and large-scale manufacturing.

Advanced Safety and Control Features

Equipped with multiple safety interlocks, operator protection is paramount. The PLC-controlled touchscreen interface streamlines monitoring and adjustments, ensuring precise operation. Centralized or manual lubrication options promote machine longevity and consistent output.

Robust Design Meeting Industry Standards

Manufactured from corrosion-resistant SS304 stainless steel, this rotary tablet press complies with cGMP standards, making it suitable for pharmaceutical, chemical, and food industries. Its sturdy structure ensures high efficiency, low noise, and reliable, continuous use.

FAQs of Tablet Making Machine:

Q: How does the tablet making machine ensure operator safety during operation?

A: The machine incorporates safety interlocks designed to prevent access to hazardous moving parts while in use. These features automatically halt operation when safety doors are opened, protecting operators from accidental injury.Q: What materials and tablet shapes can this machine handle?

A: Constructed from SS304 stainless steel, the machine is compatible with granulated material and forms tablets in round, oblong, or custom shapes according to the die configuration. It supports D, B, or BB tooling for a variety of pharmaceutical, chemical, or food applications.Q: When should I use the gravity hopper versus the force feeder system?

A: The gravity hopper is ideal for free-flowing granules, while the force feeder is recommended when processing cohesive or less-flowing powders. Choosing the appropriate feeding system ensures uniform tablet weight and consistent production quality.Q: Where is this machine typically installed for optimal performance?

A: This machine is suitable for placement in cleanrooms or manufacturing areas meeting GMP standards in pharmaceutical, chemical, or food facilities in India or globally, with access to a 220V/380V power supply and stable ambient temperatures between 10C and 40C.Q: What is the process for operating and monitoring the tablet press?

A: Operation is simplified through a PLC touchscreen control panel. The user sets the tablet parameters, fills the hopper, selects the speed, and the automated system manages compression, forming, and ejection. Real-time monitoring and adjustments can be made through the interface.Q: How do the centralized and manual lubrication systems benefit machine usage?

A: Centralized lubrication ensures even distribution of lubricant to all moving components, reducing maintenance needs and prolonging machine lifespan. The manual option is useful for targeted lubrication or specific maintenance routines.Q: What are the key benefits of using this automatic tablet making machine?

A: This machine provides high efficiency, precise tablet formation, robust construction, low noise, and ease of operation. Its compliance with cGMP standards and advanced safety features make it a dependable choice for consistent, quality tablet manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in other Category

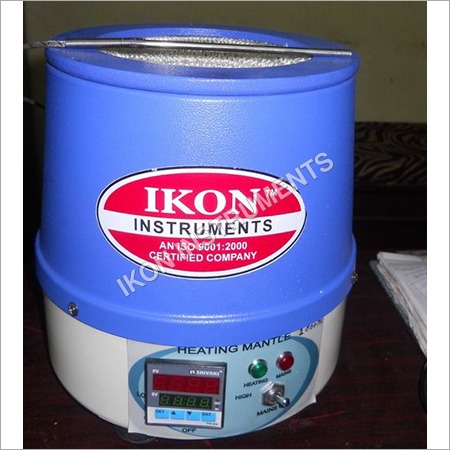

Heating Mantal Digital

Price 110000.00 INR

Minimum Order Quantity : 1 Piece

Type : Other, Laboratory Heating Equipment

Control System : Other, Digital Temperature Controller

Automation Grade : Manual

Color : Other, Blue & White

Automatic Seed Counter

Price 110000.00 INR

Minimum Order Quantity : 1 Piece

Type : Other, Automatic Seed Counter

Control System : Other, Digital Control Panel

Automation Grade : Automatic

Color : Other, White & Blue

Juice Press

Price 110000 INR

Minimum Order Quantity : 1 Piece

Type : Other, Juice Press

Control System : Manual

Automation Grade : Manual

Color : Other, Silver

BOD Incubator

Price 110000.00 INR

Minimum Order Quantity : 1 Piece

Type : Other, BOD Incubator

Control System : Other, Digital PID Control

Automation Grade : Automatic

Color : Other, White & Blue

Correspondence Address

C-241, Jhilmil Colony, Delhi - 110095

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS