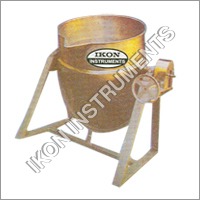

Steam Jacket Kettle

Steam Jacket Kettle Specification

- Features

- Tilting Mechanism, Pressure Gauge, Easy Discharge

- Function Type

- Heating and Cooking

- Machine Type

- Batch

- Frequency

- 50/60 Hz

- Noise Level

- Low

- Phase

- Single/Three Phase

- Heating Method

- Indirect (Steam Jacketed)

- Feeding System

- Manual

- Power Source

- Electric / Steam

- Speed Mode

- Single Speed

- Operating Temperature

- Up to 120C

- Product Type

- Cooking Equipment

- General Use

- Industrial/Commercial Food Processing

- Material

- Stainless Steel 304/316

- Type

- Steam Jacketed Kettle

- Weight (kg)

- Varies with capacity

- Product Shape

- Round or Cylindrical

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Installation Type

- Floor Mounted

- Dimension (L*W*H)

- Custom/Varies with capacity

- Raw Material

- Stainless Steel

- Feature

- Corrosion Resistant, Easy to Clean, Uniform Heating

- Color

- Silver

Steam Jacket Kettle Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Steam Jacket Kettle

We are successfully engaged in manufacturing and supplying the highly demanded Steam Jacket Kettle. Across the food industries, these kettles are extensively used for batch cooking and heating different food items. All our machines provide hassle free operations as incorporated with tilting framing arrangements. Most competitive in cost, our gamut of Steam Jacket Kettle is promptly delivered to customers at discounted prices.

Features:

- Robust in structure

- High operational efficiency

- Speedy in nature

Further Details:

Steam Jacket Kettle is used for batch heating and cooking of various food products. Mounted on a heavy duty mild steel stand with tilting arrangement. Jacket and pan are both made of the quality ss -304 grade stainless steel of heavy guage. The pan is 2/3 jacketed for maximum steam utilization and efficiency.

Capacity:

a) 25 gallon(110liters)

b) 50 gallon(225liters)

c) 100gallon(440 liters)

Superior Stainless Steel Construction

Built from high-quality 304/316 stainless steel, this steam jacketed kettle offers exceptional durability and resistance to corrosion. The material ensures hygiene and longevity, making it perfect for repeated industrial and commercial use. Whether mounted on the floor or custom-sized to fit your kitchen, the kettle maintains its silver finish and structural integrity even under demanding conditions.

Uniform Heating for Consistent Results

Thanks to indirect steam heating, the kettle distributes heat evenly across the entire surface, eliminating hot spots and guaranteeing consistent cooking or mixing outcomes. This feature is invaluable in food production, assuring that each batch meets quality standards and reducing the risk of burning or undercooking your raw materials.

Efficient and Safe Food Processing

Equipped with a manual tilting mechanism, pressure gauge, and easy discharge system, this kettle streamlines batch processing tasks. Operators benefit from straightforward manual controls, allowing for precise temperature and operational adjustments. The kettle is easy to clean, lowering downtime and fostering a hygienic work environment ideal for industrial and commercial kitchens.

FAQs of Steam Jacket Kettle:

Q: How does the steam jacket kettle ensure uniform heating during food processing?

A: The kettle uses an indirect steam jacketed heating method, distributing steam evenly around its outer layer. This design provides consistent temperatures throughout the cooking process, preventing localized overheating and ensuring all ingredients are cooked uniformly.Q: What are the benefits of having a tilting mechanism on the kettle?

A: The tilting mechanism allows effortless emptying of cooked or mixed products, reducing manual labor and minimizing food wastage. It also simplifies cleaning, promoting efficient batch turnover during industrial food processing.Q: When should I choose a floor-mounted, manual control steam jacketed kettle for my facility?

A: A floor-mounted manual kettle is ideal for industrial or commercial kitchens requiring robust batch processing solutions with hands-on temperature and mixing control. It is best suited for operations where flexibility and custom capacity are needed without advanced automation.Q: Where can the steam jacketed kettle be installed in a commercial setup?

A: This kettle is designed for floor-mounted installation in industrial kitchens, food processing plants, and commercial catering facilities. Custom sizing options ensure it can fit specific space requirements based on production capacity.Q: What is the process for cleaning the steam jacket kettle after each batch?

A: Start by using the tilting mechanism to discharge residual contents. Thanks to its stainless steel body and easy-to-clean design, washing with hot water and mild detergent will effectively remove any food residue, maintaining sanitary standards and extending the kettles lifespan.Q: How does the pressure gauge contribute to the kettles safe operation?

A: The pressure gauge monitors steam pressure within the jacket, allowing operators to maintain safe operating conditions. It helps avoid over-pressurization, ensuring consistent heating and protecting both users and ingredients during processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in other Category

Rotary Flask Shaker

Price 110000.00 INR

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Approx. 460 x 350 x 300 mm

Speed Mode : other, Variable Speed

Material : Other, Powder Coated Steel

Power Source : Electric

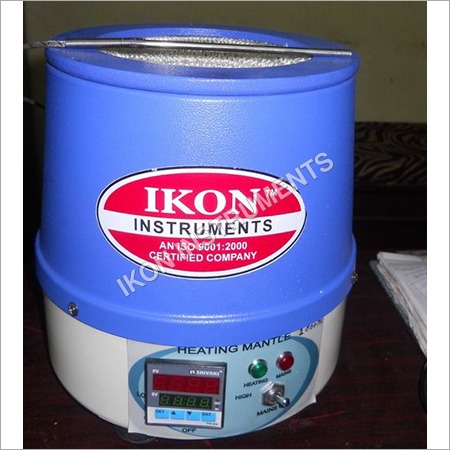

Heating Mantal Digital

Price 110000.00 INR

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 25 x 25 x 20 cm

Speed Mode : Fixed

Material : Other, Mild Steel Outer, Ceramic Fiber Inner

Power Source : Electric

Orbital Shaking Incubator

Price 110000.00 INR

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 600 x 600 x 750 mm

Speed Mode : Variable

Material : Other, Stainless Steel, Mild Steel (Exterior)

Power Source : Electric

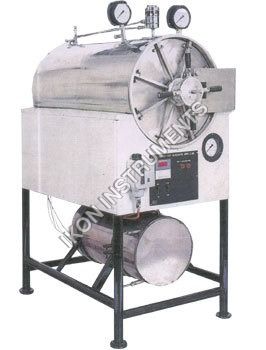

Autoclave Horizontal Cylindrical

Price 110000 INR

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Custom sizes available (e.g., 1500 x 600 x 1100 mm)

Speed Mode : other, Standard Fixed Cycle

Material : Other, Stainless Steel 304/316

Power Source : Electric

Correspondence Address

C-241, Jhilmil Colony, Delhi - 110095

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS