Lug Cap Sealing

Lug Cap Sealing Specification

- Automation Grade

- Automatic

- Power Source

- Electric

- Feeding System

- Automatic

- Features

- Safety Interlock, Adjustable Torque, Stainless Steel Construction

- Frequency

- 50/60 Hz

- Function Type

- Sealing

- Machine Type

- Sealing Machine

- Phase

- Single/Three Phase

- Speed Mode

- Variable

- Noise Level

- Low

- Product Type

- Cap Sealing Machine

- General Use

- Sealing Lug Caps on Jars/Bottles

- Material

- Stainless Steel

- Type

- Lug Cap Sealing

- Capacity

- 1500 to 1800 Bottles per Hour

- Weight (kg)

- 350 kg

- Product Shape

- Round

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based

- Installation Type

- Floor Mounted

- Power

- 1.5 kW

- Dimension (L*W*H)

- 1050 x 950 x 1650 mm

- Raw Material

- Mild Steel, SS304

- Feature

- Rust Proof, High Durability, Easy Operation

- Color

- Silver/Grey

Lug Cap Sealing Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Lug Cap Sealing

With the assistance of our technical expertise, we are capable of manufacturing and supplying a highly functional line of Lug Cap Sealing. Smooth in operations, these units are semi automatic sealer well integrated with the lever operation and easy foot switch. These are also incorporated with air filler regulator that helps in providing well maintained pressure, ensuring leak tight seal. To satisfy our valued clients, we make available the Lug Cap Sealing with easy payment modes.

Features:

- Long operational life

- Unmatched quality

- Compactly integrated

Further Details:

Lug Cap Sealing is a semi automatic sealer with easy foot switch and lever operation. It works on compressed air which ensures gentle pressure application and easy lever movement. Air filler an regulator provides recommended pressure for leak tight seal. Supplied without compressor.

Efficient and Consistent Sealing

Designed for high-volume production, this automatic machine delivers a consistent sealing output of up to 1800 bottles per hour. The computerized PLC system ensures precision and ease of operation, significantly reducing labor and error rates.

Built for Durability and Hygiene

Manufactured using rust-proof SS304 stainless steel and mild steel, the machine is built to last even in rigorous industrial conditions. The easy-to-clean surfaces and robust construction meet food and beverage safety standards.

User-Friendly Automation Features

Equipped with automatic feeding, adjustable torque, and safety interlock features, this sealer prioritizes user convenience and operational safety. Variable speed modes allow for seamless integration into different production environments.

FAQs of Lug Cap Sealing:

Q: How does the Automatic Lug Cap Sealing Machine operate?

A: The machine uses a computerized PLC-based control system, automatic feeding, and variable speed modes to efficiently place and seal lug caps on round jars and bottles. Its intuitive controls make operation straightforward and require minimal manual intervention.Q: What types of containers is this sealing machine compatible with?

A: It is designed for round bottles and jars that require lug cap sealing, accommodating various sizes commonly used in the food, beverage, and pharmaceutical industries.Q: When should a manufacturer use this equipment in the production process?

A: This machine should be implemented after the filling stage and immediately before labeling or packaging. It ensures each container is securely sealed, maintaining product integrity and shelf life.Q: Where is the best place to install this machine in a production setup?

A: The floor-mounted unit should be stationed in the post-filling section of the bottling or canning line, in a clean, flat area with access to single or three-phase electric power and adequate ventilation.Q: What is the process for adjusting speed or torque on this machine?

A: Operators can easily adjust the sealing speed and torque through the PLC interface, allowing adaptation to different bottle sizes, cap types, or production targets without complex manual changes.Q: How does the machine ensure operator safety during use?

A: It features an integrated safety interlock system that prevents operation if panels are open or unsafe conditions are detected, minimizing risk and ensuring compliance with industrial safety protocols.Q: What are the main benefits of using this lug cap sealing machine?

A: Manufacturers benefit from high throughput, consistent sealing quality, easy operation, and low maintenance due to its rust-proof, durable stainless steel construction. Its automation significantly reduces labor costs and improves production efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in other Category

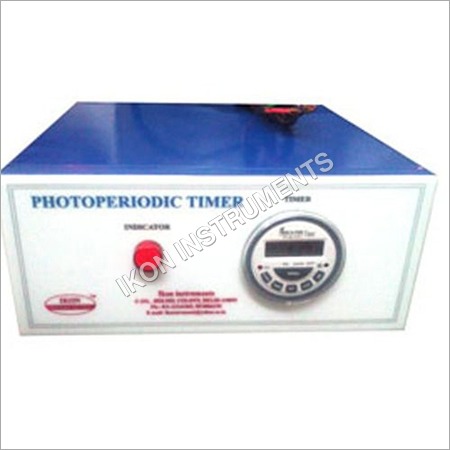

Photo Periodical Timer Digital

Price 110000 INR

Minimum Order Quantity : 1 Piece

Noise Level : Silent Operation

Feature : Other, Timecontrolled switching, Reliable operation

Product Shape : Other, Rectangular

Raw Material : Other, ABS Plastic

BOD Incubator

Price 110000.00 INR

Minimum Order Quantity : 1 Piece

Noise Level : Low

Feature : Other, Uniform Temperature, Auto Defrost, Alarm System

Product Shape : Other, Rectangular

Raw Material : Other, Stainless Steel & Mild Steel

Juice Press

Price 110000 INR

Minimum Order Quantity : 1 Piece

Noise Level : Low

Feature : Other, Corrosion Resistant

Product Shape : Other, Rectangular

Raw Material : Other, Stainless Steel

Wrist Action Shaking Machine

Price 110000.00 INR

Minimum Order Quantity : 1 Piece

Noise Level : Low

Feature : Other, Variable Speed, Smooth Shaking Motion

Product Shape : Other, Rectangular

Raw Material : Other, Mild Steel Body

Correspondence Address

C-241, Jhilmil Colony, Delhi - 110095

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS